Biogas technology lowers costs

Posted on: 2026-01-29

By: Steve Last

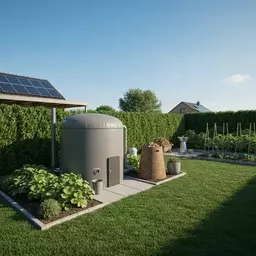

Turning Waste into Wealth: The Economic Case for Biogas

Imagine a scenario where your organization’s most significant liability—waste—suddenly becomes its most reliable asset. In an era where operational efficiency is synonymous with survival, the traditional "take-make-dispose" model is bleeding professional industries of capital. Biogas technology does not just offer a green badge of honor; it offers a fundamental restructuring of balance sheets. By converting organic refuse into renewable energy and nutrient-rich byproducts, businesses are discovering that the path to substantial cost reduction is paved with the very materials they used to pay to throw away.

The Mechanics of Cost Reduction

The adoption of biogas technology via anaerobic digestion (AD) is not merely an environmental decision; it is a strategic financial maneuver. For industries ranging from agriculture to food processing and wastewater treatment, the installation of a biogas system addresses three critical financial pressure points: waste disposal, energy procurement, and input material costs.

Transforming Waste Liability into Asset Liquidity

The most immediate financial impact of biogas implementation can the drastic reduction in waste management overheads for food waste biogas plants.

For large-scale operations, waste disposal is a massive line item. Landfill taxes and "tipping fees" are rising globally as regulations regarding organic waste tighten. Biogas digesters allow facilities to process organic waste on-site.

-

Direct Savings: By diverting waste from landfills, companies eliminate the cost per ton charged by waste management haulers.

-

Logistical Efficiency: Reducing the volume of waste that needs to be transported lowers fleet fuel costs and vehicle maintenance expenses.

Energy Independence and Volatility Mitigation

Energy markets are notoriously volatile. Reliance on the grid leaves operations vulnerable to price spikes and peak-demand charges. Biogas systems capture methane—a potent greenhouse gas—and convert it into electricity and heat (Combined Heat and Power, or CHP).

Stabilizing OPEX via On-Site Generation

Generating renewable energy on-site creates a hedge against fluctuating utility prices.

-

Electricity Offset: The electricity generated can power facility machinery, lighting, and HVAC systems, significantly lowering the monthly utility draw.

-

Thermal Application: The heat byproduct from the engine can be captured and utilized to heat the digester itself or for facility process heat (e.g., pasteurization, drying), increasing total system efficiency to over 85%.

Secondary Value Streams: The Circular Economy

Beyond energy and waste, biogas technology creates tangible products that can replace purchased inputs.

Digestate: Monetizing the Byproduct

The material left over after anaerobic digestion, known as digestate, is a nutrient-rich substance that retains the nitrogen, phosphorus, and potassium (NPK) of the original feedstock but in a more plant-available form.

Replacing Synthetic Fertilizers

For agricultural operations, digestate serves as a direct substitute for expensive synthetic fertilizers.

-

Cost Avoidance: Farms can utilize their own digestate, slashing the budget required for chemical fertilizers.

-

Revenue Generation: For non-agricultural industries (like food processing plants), high-quality digestate can be processed, dried, and sold to local agricultural partners or gardening markets as a soil amendment, creating a new revenue stream.

FAQs

Q: What is the typical ROI period for a commercial biogas plant? A: The Return on Investment (ROI) varies based on feedstock quality and local energy prices, but efficiently managed commercial systems typically see an ROI between 3 to 7 years.

Q: Does biogas technology require specialized staffing? A: While modern systems are highly automated, they do require monitoring. Most facilities upskill existing maintenance staff rather than hiring new specialists, though some engage third-party management firms for optimization.

Q: Is biogas technology viable for small-scale operations? A: Historically, biogas was favored by large operations due to economies of scale. However, recent advancements in modular and scalable "micro-digester" technology have made it cost-effective for smaller farms and processing facilities to adopt the technology.

Q: How does this impact carbon tax liabilities? A: By capturing methane (which is significantly more potent than CO2) and displacing fossil fuel usage, companies can generate carbon credits. These credits can often be sold on carbon markets, providing an additional financial incentive.

What if a simple technology could transform the lives of refugees living in camps? Biogas projects a

What if a simple technology could transform the lives of refugees living in camps? Biogas projects a

As the demand for renewable energy solutions grows, understanding anaerobic digestion can transform

As the demand for renewable energy solutions grows, understanding anaerobic digestion can transform

As the world shifts towards more sustainable practices, have you considered how your organic waste c

As the world shifts towards more sustainable practices, have you considered how your organic waste c