This video shows how to make a simple small Gobar Gas Digester (Cow Dung Biogas Plant) as an experiment.

It includes details of the design and construction, but you will need to watch carefully for the design details because they are shown in diagram form during the video. This demonstration is by the Pakistan Biogas Club. It is in Urdu with English subtitles.

Biogas is produced by using cow dung or food waste. Also, decomposable organic material such as kitchen waste by the process of anaerobic digestion.

More About Making Biogas

Introduction

Gobar gas is an eco-friendly renewable energy source. Gobar gas units convert cow dung and human excreta into biogas. This gas is used for cooking and lighting. The gobar gas unit can be established in farmhouses or households with cattle or buffaloes.

Such units are common in rural areas [especially in Pakistan and India]. Also, low-water consuming toilets can be processed in this unit type. The wastes from these units can be used for gardening. via www.indiamart.com

Biogas is a biofuel and it generally refers to the gas produced from organic matter as it is broken down by biological means.

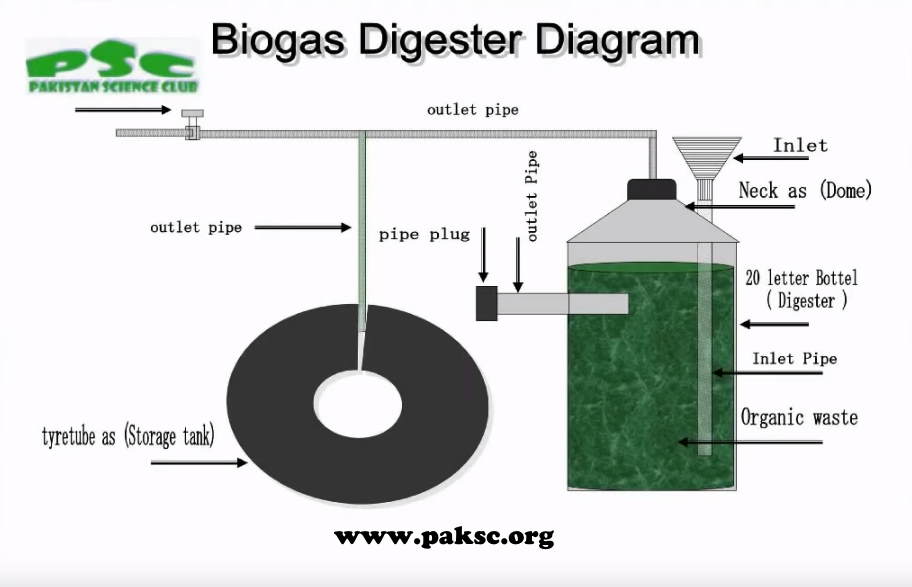

Image Copyright Pak Science Club

Image Copyright Pak Science Club

You can build a biogas plant for your home, or community, at a much larger commercial scale or a school project. Information, plans and designs are here for a range of applications. Biogas is often referred to as ‘gobar gas' in India, a word derived from Hindi meaning cow dung.

What is Gobar Gas?

The biogas produced from a digester [gobar gas] is comprised primarily of methane, carbon dioxide and other trace gases.

When you build a biogas plant, methane, hydrogen, carbon monoxide and other trace gases are produced but methane is the main combustible gas.

Biogas is currently used as a low-cost fuel in many countries for heating and cooking and is also extracted from waste management facilities like sewage plants and landfill sites where it is refined into biomethane and used to run engines to generate electricity. via www.build-a-biogas-plant.com

Why Make Gobar Gas?

It is far superior to cooking with wood. Don't worry, there is no longer any bad smell from the dung, sewage, or livestock manure etc. that it is made from

Cooking by biogas is much cleaner than cooking over a wood fire. There is no smoke to cause lung problems and eye diseases.

How to Load and Feed the Home Kitchen Waste Unit to Start the Digestion

Begin by loading the fermentation chamber with the materials to be fermented (manure or other wastes). You should begin with an initial load of 300 – 500 kg of materials for each cubic meter of the fermentation chamber.

This needs to be supplemented by an additional 8- 10 kg each day for each cubic meter of the fermentation chamber. The gas output will be 250 – 400 litres for each cubic meter of the chamber. via paksc.org

What Size Methane Generator is Needed?

If generating methane from manure, collect dung for several days to determine average daily dung production. On this basis, the appropriate size biogas digester plant can be calculated.

For example, where 55 kg of dung a day is available, an 8 m³ plant is warranted; where it’s only 6 kg of dung a day, a 1 m³ plant will suffice.

The average is around 1 month – so gauge how much material you will add each day, and multiply it by 30 to calculate the size of the digester. via bio-gas-plant.blogspot.com. [These guidelines assume a warm climate such as in India or Pakistan.]

Applications of Digester and the Output (Digestate)

Plant output can be used as manure. Mosquito and Odour free. Low maintenance and portable. Suitable for homes, hotels, fish markets, etc.

Plant output can be used as manure. Mosquito and Odour free. Low maintenance and portable. Suitable for homes, hotels, fish markets, etc.

Can be installed over rooftop and garden. Suitable for both rural and urban areas. Motive Power can be produced by linking the Gobar Gas to a dual-fuel engine, specially designed for Gobar Gas. via agriculturegoods.com

Safety Warning:

Biogas can be explosive when mixed in the ratio of one part biogas to 8–20 parts air. Special safety precautions have to be taken for entering an empty biogas digester for maintenance work.

It is important that a biogas system never has negative pressure as this could cause an explosion. Negative gas pressure can occur if too much gas is removed or leaked; Because of this biogas should not be used at pressures below one column inch of water, measured by a pressure gauge. via en.wikipedia.org