In this article, we discuss Sewage Sludge Heavy Metals and Biosolids. This is an increasingly important subject now that many more new sewage sludge-fed biogas digesters are being built around the globe.

Sewage sludge is a product of wastewater treatment. It is the solid part of sewage. The danger from sludge, from pathogens, is removed by pasteurization.

However, concern still arises according to the extent to which industrial waste effluent is disposed to sewers and therefore heavy metals may be present, plus the possibility of many other hazardous materials as well.

Pathogens are not a significant health issue if the sludge is properly treated and site-specific management practices are followed, and are only a concern when it is placed on land or co-digested with other organic waste such as food waste which is not then also pasteurized.

Sewage sludge refers to the solids separated during the treatment of municipal wastewater (including domestic septage), while biosolids refer to treated sewage sludge that meets the EPA pollutant and pathogen requirements for land application and surface disposal. EPA defines biosolids as treated or processed sewage sludge that can be beneficially recycled. Others complain that the word Biosolids is a made-up euphemism for sewage sludge that has no scientific or legal basis.

After treatment, and dependent upon the quality of sludge produced (for example with regards to heavy metal content), sewage sludge is most commonly either disposed of in landfills, dumped in the ocean or applied to the land for its fertilizing properties.

After treatment, and dependent upon the quality of sludge produced (for example with regards to heavy metal content), sewage sludge is most commonly either disposed of in landfills, dumped in the ocean or applied to the land for its fertilizing properties.

Pollutants in sewage sludge can limit its agricultural use. You must only use sludge that has been tested according to the Sludge Regulations. Heavy metal contaminated sludge is not normally applied to land, although it may be for short periods. But, only with great care that the soil-metal content does not build up to exceed safe levels.

It is usually mixed with primary sludge from the primary clarifiers and undergoes further sludge treatment for example by anaerobic digestion, followed by thickening, dewatering, composting and land application. Once treated, sewage sludge is then dried and added to a landfill, applied to agricultural cropland as fertilizer, or bagged with other materials and marketed as biosolid compost for use in agriculture and landscaping.

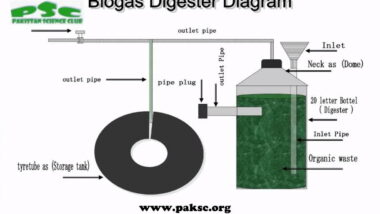

In many countries, an increasing percentage of it has been thermally treated as a result of concerns about land spreading and landfilling of organic and inorganic contaminants. However, incineration, which was once highly favoured for its disposal is no longer favoured. The cost of the energy needed to dry it and fire the incinerator has become a huge burden. To use incineration makes no sense any longer anyway because the renewable energy (biogas) exporting use of the anaerobic digestion process is now the better option.

Digested sewage sludge is usually dewatered before disposal. It is the solid, semisolid, or slurry residual material that is produced as a by-product of wastewater treatment processes. It is usually dewatered before disposal.

Air pollution control is a very important consideration when sewage sludge is incinerated. More cost is introduced to the incineration process as air quality standards improve, due to the expensive and energy-sapping characteristics of the glue clean-up equipment.

Anaerobic digestion of sewage sludge can be profitable, but it is almost impossible to say whether extracting these metals from it is economically feasible. The reduction of heavy metals in it can be achieved by source control of discharge to sewer systems by outlawing the discharge of metals into sewage.

Water Utility Companies are encouraging the waste industry to look upon sludge as a resource and not a disposal burden. There may also be another source of revenue for AD Plant owners when land application of treated sewage sludge (digestate) is allowed, which can reduce significantly the sludge disposal cost component of sewage treatment as well as provide a large part of the nitrogen and phosphorus requirements of many crops.

Production of sludge can be reduced by conversion from flush toilets to dry toilets such as urine-diverting dry toilets and composting toilets. If applied to land in a safe manner, preferably after anaerobic digestion it can supply a large part of the nitrogen or phosphorus that most crops need.

A more detailed report on the health risks from pathogens associated with land application of sewage sludge can be found in “Hazards from pathogenic microorganisms on land-disposed sewage sludge”, which outlines the range of pathogens found in sludge and their longevity in the soil.

In one recent study, it has been suggested that sewage sludge can be applied as an initial fertility driver for mudflat soil amendment, which provides an innovative solution for arable land resources and solid waste disposal.

But, despite positive soil structural effects, the amounts of it that can be added to arable land are rather limited. This remains the position when all sludge is distributed equitably on agricultural land and when the permissible quantity per hectare is applied.

Standards for the Use or Disposal of Sewage Sludge, Part 503, establishes the general requirements, pollutant limits, operational standards, and management practices. in addition, it sets the frequency of monitoring, record keeping, and reporting requirements, that apply to the sludge that is land applied, placed on a surface disposal site, or fired in a sewage sludge incinerator (see 58 Federal Register 9248, February 19, 1993).

Any treatment that works with sewage sludge that does not meet the standards for the use or disposal consent must clean up its influent. (This can be done, for example, by strengthening pretreatment or pollution prevention programs), improve the treatment of it (for example, by reducing the densities of pathogenic organisms), or select another sewage sludge use or disposal method.

Existing technology can produce biodiesel fuel from municipal sewage sludge that is within a few cents a gallon of being competitive with conventional diesel refined from petroleum, according to an article in ACS’ Energy.

A constant percentage of return activated sludge is adjusted based on measuring the inflow of the sewage plant. Return activated sludge is returned to the biological anoxic selector for the reintroduction of bacteria to the treatment process and waste activated sludge is pumped to the gravity sludge thickener in preparation for stabilization in the aerobic digestion system. The portion of the sludge blanket which is not returned to the aeration step in the BAS process as return activated sludge is transferred as waste-activated sludge to a solids treatment process.

It is recognized that whether the return activated sludge is fed continuously or in batches, electronically controlled valves and other instrumentation as known in the art may be installed to automate the process. The return activated sludge can be very dilute and also constitutes only fine particles.