Biogas digesters make biogas, in other words, simple gobar gas plants make raw biomethane. But, what is biogas? Biogas typically refers to a gas produced by the biological breakdown of organic matter in the absence of oxygen. Organic waste such as dead plant and animal material, animal faeces, and kitchen waste can be converted into a gaseous fuel called biogas. Biogas originates from biogenic material and is a type of biofuel.

What Conditions are Needed for Biogas Digestion to Take Place?

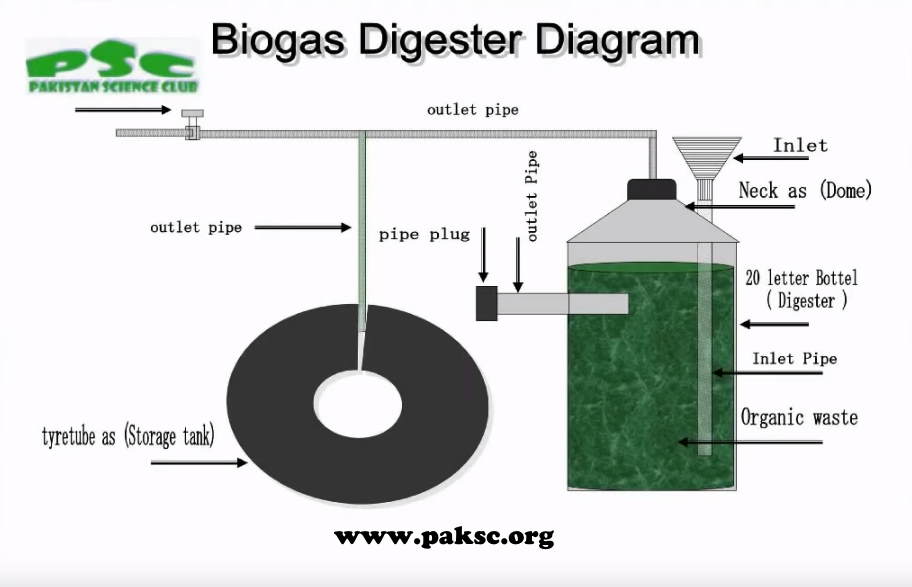

Anaerobic processes either occur naturally or in a controlled environment such as a biogas plant. Organic waste such as livestock manure and various types of bacteria are put in an airtight container called a digester so the process could occur. The picture to the right below shows a biogas digester at a dairy farm in Cottonwood, California. Depending on the waste feedstock and the system design, biogas is typically 55 to 75% pure methane. State-of-the-art systems report producing biogas that is more than 95% pure methane (biomethane).

Why Are Biogas Plants Most Common in Tropical Countries?

Biogas digesters are most common in tropical countries because the microbes that do the magic require warm weather to proliferate 70- to 80-degree temperatures are needed day and night for optimal performance. In colder climates, they are often placed in a greenhouse or underground for insulation. Otherwise, some form of artificial heat must be provided to ensure a reliable source of fuel in the winter months which defeats the purpose, of course. Summer-only operation is always an option.

How Does Biogas Production Reduce Reliance on Fossil Fuels

Advocates for sustainable energy have promoted the biogas digester as one option which could be used to reduce reliance on fossil fuels. In addition to providing sustainable energy, biogas digesters are also low cost, efficient, and easy to maintain. This makes them an excellent tool for organizations which attempt to empower communities by providing them with tools they can maintain and use themselves, rather than just giving aid, which can cause communities to become dependent on outside assistance.

The development of a biogas digester program partly solves energy problems as well as environmental pollution in the country. Plus, another surprising benefit is described in the next section.

Digestion of Farm Wastes is Much Needed as a Waste Management Technique

One of the major applications for biogas digesters is in the disposal of human and farm waste. In many developing nations, controlling human waste is a major issue, and so is the availability of energy. By providing communities with biogas digesters, organizations and the government could help contribute to improvements in public health while also providing communities with a source of sustainable energy. Farms, which can generate large volumes of animal waste, can also utilize biogas digesters to power their operations or to generate power which can be traded or sold.

Returning to the Subject of Hogs How Much Gas is Made Per Pig?

It is estimated that an 8 m³ simple gobar gas plant household biogas tank can treat the manure from 4 to 6 pigs, yielding around 385 m3 biogas annually. It can save 847-1,200 kg of coal-based on the calculation of effective heat equivalent. According to the methodology recommended by IPCC in 2006, if a household biogas digester treats the manure of 4 pigs, it can reduce GHG by 1.5~5.0 tonnes CO2e.

How to Obtain These Benefits via Practical Biogas https://biogas-digester.com/biogas-digester/biogas-digester-for-home-useDigester Solutions

The main breakthrough is the utilization of polyethylene plastic tubes for the digester that is simple and easy to maintain.

Maize flour is an excellent feedstock for a biogas digester. One would get about 250 g of methane from 1 kg of maize flour. Methane would have a calorific value of about 11000kCal/kg. So the 250 g would have about 2750 kilocalories.

Various studies have been conducted to maximize the use of the products of biogas technology. China conducted a study on the supplementation of anaerobically digested effluent to animal feeds. It is aimed to utilize digester sludge as a feed substitute for hogs. The two test groups received the dighttps://biogas-digester.com/guide-to-biogas-digestateester sludge substitute while the last test group was the control group which received the basic ration (100% commercial feeds) of the biogas and the sludge. The result was a successful 15% to 20% feed augmentation using digestate to feed the hogs. Clearly. a great many questions arise about the wisdom of so doing, nevertheless, the research showed potential for additional benefits from biogas digestion.

The Need for Efficient Biogas Reactor Mixing

The physical parts involved in any digester are biogas, scum, supernatant, digested slurry, digested sludge and inorganic solids. If the content of the Biogas Digester is not stirred or disturbed for a few hours then these by-products get formed into different layers inside the digester. The heaviest by-product, which is Inorganic Solids will be in the bottom-most portion, followed by Digested Sludge, and so on and so forth as shown in the three diagrams for three different types of the digester.

The Importance of pH to Anaerobic Digestion

For a biogas digester to produce gas, it needs methane-producing bacteria. After the methane-producing bacteria is introduced, the bacteria will reproduce and the process continues infinitely, and there is no risk that the bacteria will die. Once the bacteria are introduced, the process of biogas production will never stop.

Nevertheless, the pH value of the fermenting liquid has an important impact on the biological activity of biogas bacteria. Normal biogas fermentation requires the pH value to be between 7 and 8. During the normal process of biogas fermentation in a rural digester, the pH value undergoes a naturally balanced process, in which it first drops from a high value to a low value, then rises again until it almost becomes a constant. This process is closely related to the dynamic balance of three periods of biogas fermentation. After feeding the biogas digester, the time that the pH value takes to reach its normal level depends on the temperature and the kinds and amounts of raw materials that are fed in.

For a biogas digester to produce gas, it needs methane-producing bacteria. After the methane-producing bacteria is introduced, the bacteria will reproduce and the process continues infinitely, and there is no risk that the bacteria will die. Once the bacteria are introduced, the process of biogas production will never stop.

Starting Up a Biogas Plant

The digester should be filled as quickly as possible. The following steps should be kept into consideration: a) Be sure to open all valves to relieve any pressure buildup in the digester dome before putting any slurry into the digester. Starter/Seeding.

Filling the digester

10% of the total slurry volume should be added when the digester is about 25% full. Cattle dung is a good starter since cattle have methane-producing bacteria in their stomachs. the biogas should be properly maintained to achieve efficient operation.

Conclusion – the Key to Biogas Production

Key in biogas production is the construction of a proper container (an anaerobic biogas digester) that is air-tight (and safe). When organic materials such as dung, vegetable matter, or sewage break down in the absence of large amounts of oxygen (where anaerobic bacteria cause the desired decomposition) the result is a production of useful quantities of methane (CH4) that can be used as a fuel, along with carbon dioxide, and lower amounts of hydrogen and other trace gases.