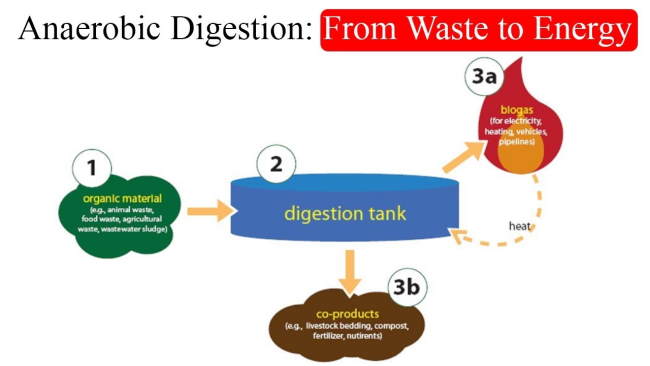

So, you would like to know what are AD Plants? Here we bring you the AD Plant Information. Put simply, an AD plant is a shortening of the term anaerobic digestion plant.

What is mainly used for the production of biogas and placed inside the fermenter (a special container) are agricultural wastes, manure, food scraps etc. Also, sludge from wastewater treatment plants is used.

Animal Manure and Field Biomass from Agriculture

Not all biogas is created equal. Biogas can be processed to about 95% CH4 – what is often called biogenic CH4 or renewable natural gas (RNG).

When biogenic CH4 is combusted (on a stovetop burner, for instance) it still creates CO2 emissions, but since the biogas is derived from plants (which naturally remove CO2 from the atmosphere), the CO2 emissions are generally considered climate-neutral as relatively little fossil carbon is added to the atmosphere.

What Steps Should I Follow to Achieve my “What are AD Plants?” Project?

The energy was so cheap that even those running those incinerator plants failed to truly realize that they were using energy, to destroy energy! that was an expensive waste, which is now being put right as large numbers of sewage sludge incinerators are being shut-down and replaced with biogas plants.

The latest AD plants can be so efficient in making power that they can generate enough electricity to run the entire wastewater treatment works (sewage works) solely using the sludge from the works as their bio-fuel!

These are just two examples of the way that the anaerobic digestion and biogas industry is now growing.

AD Plant Batch and Continuous Processes

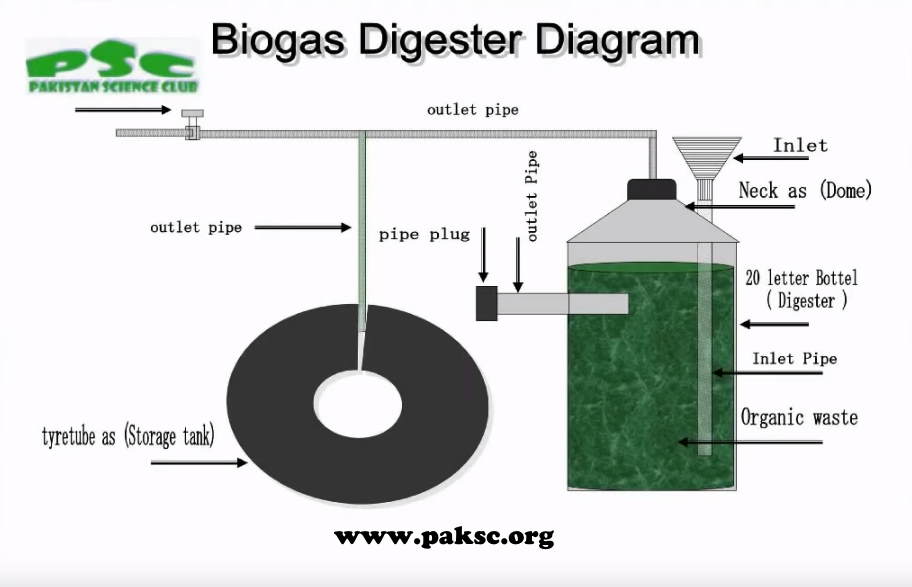

Anaerobic digestion can be performed as a batch process or a continuous process. In a batch system, biomass is added to the reactor at the start of the process. The reactor is then sealed for the duration of the process. In its simplest form batch, processing needs inoculation with already processed material to start the anaerobic digestion. In a typical scenario, biogas production will be formed with a normal distribution pattern over time.

There is an increased international interest in the use of biomass to sustainably produce liquid biofuels to meet future energy.

AD Plant Technical Challenges

However, there are many technical challenges associated with this promising technology. Anaerobic digestion/biogas production is an ideal synergistic process to the algal biofuel production and could help to satisfy the local parasitic energy demand of the biofuel production process, in a similar way to how it is currently used in wastewater treatment. The potential synergies include nutrient recycling, residue valorization, biogas upgrading to biomethane, and reduced water use. This project will develop knowledge in the integration of these two technologies using a multi-disciplinary approach involving process, biochemical, and CFD modelling supported by bench-scale experimental work. The student will benefit from links with the industry.

Environmentally Safe Waste Management and Disposal

Anaerobic digestion of biomass offers two important benefits of environmentally safe waste management and disposal, as well as the generation of clean electric power. The growing use of digestion technology as a method to dispose of livestock manure has greatly reduced its environmental and economic impacts. Biomass-to-biogas transformation mitigates GHGs emissions and harnesses the untapped potential of a variety of organic waste. Anaerobic digestion technology affords greater water quality benefits than standard slurry storage due to lower pollution potential. It also provides additional benefits in terms of meeting the targets under the Kyoto Protocol and other environmental legislation.

Is AD Using Food Crops and Raising Food Prices in the UK?

The volume of agricultural biomass (crops, feedstock, and grazing) produced has stayed relatively stable between 2000 and 2015, however, the volume of crops produced (arable and horticultural crops, and feedstock) increased by 20% between 1997 and 2015, whilst grazed biomass (an estimate of grass and other vegetation consumed by animals) fell. The large increase in production and value between 2013 and 2014 is partly attributable to favourable weather conditions in 2014.

AD Fixed-Film Type Digester

The fixed-film digester immobilizes bacteria on packing material, or media, within the reactor vessel, thereby preventing washout of microbial biomass. This design typically handles a solids content of < 2% and can operate at ambient or higher temperatures. At ambient temperature, the lower rate of metabolism is offset by a high microbial mass. HRT is in the order of 2-4 days. Fibrous solids are removed prior to digestion.

The Complexity of AD Systems

Digestion systems can be configured with different levels of complexity In a single-stage digestion system (one-stage), all of the biological reactions occur within a single, sealed reactor or holding tank. Using a single-stage reduces construction costs, but results in less control of the reactions occurring within the system.

Acidogenic bacteria, through the production of acids, reduce the pH of the tank.

Methanogenic bacteria, as outlined earlier, operate in a strictly defined pH range. Therefore, the biological reactions of the different species in a single-stage reactor can be in direct competition with each other. Another one-stage reaction system is an anaerobic lagoon.

AD and Renewable Energy from Organic Wastes

Anaerobic digestion (AD) provides possibilities to produce renewable energy from organic wastes in decentralized sites, producing methane-rich biogas from manure (human and animal) and crop residues.

Conclusion: What are AD Plants?

Apart from supplying renewable energy AD plants have other positive effects including the strengthening of closed-loop recycling management systems, reducing emissions from manure storage, and producing a valuable organic fertilizer. It can also create new sources of income for farmers. Currently, less than one percent of the potential benefits from AD are being used. Reasons for these include obstacles such as the legislative framework and the lack of economic incentives for potential investors.

Manure is not the only waste that is a rich source of energy. What you might think is “just garbage,” might actually be turned into energy.

Dead plants, rotting food, wood chips, sawdust, leftover crops, nutshells, and paper products are all examples of biomass, which are natural materials or organic matter that can be used to make energy.